Chute and Hopper Liners Wear Plate/Dragline Bucket Q345 Steel Base Plate High Ccr Clad Liner Plate

Description

Basic Info

| Standard | JIS, DIN, BS, ASTM |

| Application | Loader, Construction Machinery, Metallurgical Machinery, Cement Plant, Mining Machine, Thermal Power Plant, Coal Yard |

| Material | Steel |

| Type | Wear Resistant Plate |

| Length | 3000mm, 3400mm, 3500mm, Customized |

| Width | 1.4 M, 2.1 M, Customized |

| Grade | Chrome Carbide Overlay Plate |

| Processing Service | Bending, Welding, Cutting, Pun |

| Product Name | Chromium Carbide Plate |

| Alloy or Not | Is Alloy |

| Delivery Time | 15-21 Days, 14 Days |

| Chemical Composition | C: 3.0~5.0 % Cr: 25~40 % |

| Microstructure | Above 50% Volume Fraction Chromium |

| Wear Resistance | Super Good |

| Heat Resistance | up to 900 °c |

| Machinery Properties | Cut, Bend, Punch, Bolt, Weld |

| Special Use | Bimetallic Steel Plate |

| Technique | Hardfacing/Cladding/Surface Welding |

| Transport Package | Steel Pallet, Non Fumigation Pallets |

| Specification | 1.4*3.4m, 1.4*.3.0m, 1.4*3.5m, 2.1*3.5m, customize |

| Trademark | RPIC |

| Origin | Rizhao, China |

| HS Code | 72109000 |

| Production Capacity | 3000000 Square Meters Per Year |

Product Description

| Product Name | Hardfacing bimetal steel plate wear resistant plate |

| Brand | RPIC |

| Base Plate | Q235/Q345. |

| Hardfacing layer | High chromium high carbide overlay. |

| Chemical Composition | C(%): 3.0-5.0 ,Cr(%): 25-40. |

| Microstructure | The carbide (Cr7C3) volume fraction on the microstructure is above 50%. |

| Hardness | HRC58-65. |

| Surface Treatment | Hardfacing,clading,coated. |

| Technique | Hardfacing,open arc welding,submerged arc welding. |

| Wear Resistance | High wear resistance,30 times higher than low carbon steel and 12 times than heat treated steel. |

| Impact Resistance | Medium. |

| Flatness tolerance | ±3mm/m. |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0-0.5mm. |

Main Thicknesses

| 3+3,4+4, 5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12 14+6,14+8,14+10,16+6,16+8,16+10 18+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10 Customized. |

| Plate Size | Open arc welding wear plate:1400*3400mm Submerged arc welding wear plate:1400*3000mm, 1400*3500mm, 2100*3500mm. Customized. |

| Place of Origin | China |

Application | Mining,Steel,Cement,Power,Port,etc. |

RPIC wear resistant steel plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC 58~65 and depends on the overlay's thickness.

The main ingredients of wear plate are C (%): 3.0~5.0 and Cr (%): 25~40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles thoughout the layer will guarantee a super wear resistant surface.

The overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm, reaching up to 350 Mpa in our tests.

Our company R&D producted bimetallic wear plate have four different types:

1. generally wear plate with Open arc welding: base plate + chromium carbide abrasion resistant welding layer with good abrasion resistance, Hardness HRC 55-63 (HV 600-780) and chemical compostion C: 2.5-5.0 % Cr: 20-30 %

2. super wear plate with Submerged arc welding: base plate + high chromium carbide abrasion resistant welding layer with super good abrasion resistance, Hardness HRC 58-65 (HV 600-780) and chemical compostion C: 3.0-5.5% Cr: 25-40%

3. wear plate with Impact resistance: base plate + chromium matrix with other metallelementes resistant welding layer with good impact resistance and super good abrasion resistance

4. wear plate with Heat resistance: base plate + chromium matrix with other metallelementes resistant welding layer with good heat resistance (up to 900 °C) and super good abrasion resistance.

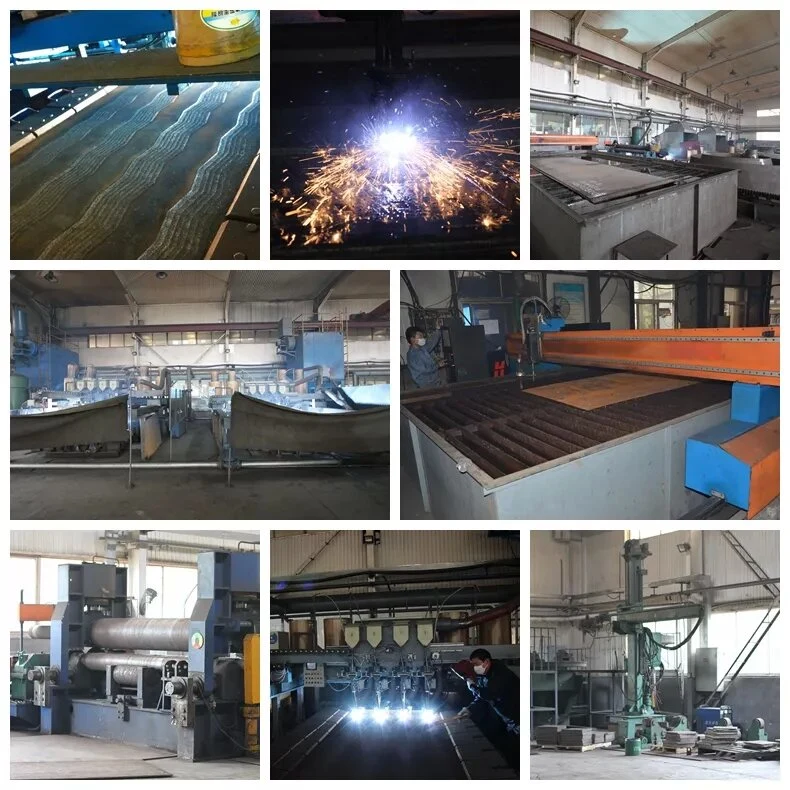

Company ProfileRPIC is a comprehensive enterprise which engages in design, manufacture, installation and maintenance of the bulk-handling equipments. It is the wholly-owned subsidiary of the listed governmental company Rizhao port

It has the Second-level Qualification of the Machinery&Electrical Equipments installation Enterprise. Our steel structures and frames production capacity is 160, 000 tons/year, the main products are belt conveyor, stacker-reclaimer machine, car loader machine, un-loader machine, etc. Widely used in ports, mining, food, power plants and other industries. We begin to make belt conveyor from the year 1993, and has lots of large contracts of manufactures and installation projects. In the year of 2005, we rely on our own technological superiority, self-design and manufacture the storage capacity of 9000 T/H of the stocker, as a national origination.

Packaging & Shipping

Packaging: Steel pallet, Non fumigation pallets, plastic film, Customized

Packaging Size: customized. Loading into 20ft or 40ft Contraner.

Delivery Detail: Generally 7-15 days, it is according to quantity.

Q1:Can you send samples?

A:Of course, we can provide customers with free samples but customer should pay the courier fee.Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement and quantities you need to purchase.

Q3:What about product prices information?

A:Prices various according to periodic price changes of raw materials.Q4:What is your terms of payment ?

A: 30% T/T in advance ,balance before shipment or 100% LC at sight.Q5.Do you provide customer made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.Q6:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.Q7: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Thailand, Myanmar, Vietnam, and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.Q8:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.Q9:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, customers can appoint third parties to inspect the products before loading too.Q10:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.Q11:What is your working time?

A:In general, our online service time is Beijing time: 8:00-22:00, after 22:00, we will reply to your inquiry in the coming working day.

Our Contact