ASTM AISI Aluminum Base Copper Clad Laminate PCB Raw Material Double Layer Copper Clad Laminate Sheet Plate

Description

Basic Info

| Standard | ASTM |

| Model No. | T2 H65 H62 C1100 C1220 C2400 C2600 C2600 C3712 Tu2 |

| Product Name | Copper Cathode Tinned Clad Copper Sheets |

| Cu (Min) | 80-99.99% |

| Thickness | 2-50mm |

| Width | 600-2500mm |

| Length | 1000-120000mm |

| Hardness | 1/2 Hard/1/4hard/ Hard |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Transport | Sea-Worthy Package |

| MOQ | 1ton |

| Surface | Black/Galvanized /Oiled/Pickled |

| Delivery Time | Fast Delivery, Within 5-7 Days |

| Edge | Mill Edge, Slit Edge |

| Tolerance | +/-0.1mm |

| Sample | Avaliable |

| Transport Package | Standard Packing |

| Specification | 4X8FT/5X10FT/Customize |

| Trademark | XINHUA SHEGNDA |

| Origin | China |

Product Description

Copper Plate-made of pure copper or copper alloy in various shapes including rods, wires, plates, strips, tubes, foils,etc., collectively referred to as copper.Copper materials include copper plates, copper rods, copper tubes, copper strips, copper wires, copper bars, copper materials.1. The surface of the hot rolled plate should be clean; Delamination, cracks, peeling, inclusion, and green rust are not allowed, but repair is allowed, and the thickness of the plate should not exceed the allowable deviation after repair.The surface of the hot rolled plate is allowed to have slight and local scratches, spots, pits, pressed objects, wrinkles, rollermarks and other deviations that do not make the thickness of the plate exceed the allowable deviation.

2. The surface of the cold rolled plate should be smooth and clean; Delamination, cracking, peeling, inclusion, and green rust are not allowed.The surface of the cold-rolled sheet is allowed to have slight and local scratches, spots, pits, pressed objects, wrinkles, roller marks, oil marks, and other deviations that do not make the thickness of the sheet exceed the allowable deviation.

| Product Name | Copper plate/Sheet |

| Thickness | 0.1mm-120mm |

| Material | T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,TP1,TP2,C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,TU1,TU2,C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70600,C70620,C71000,C71500,C71520,C71640,C72200,etc |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,etc |

| Surface | mill, polished, bright, oiled, hairline, brush, mirror, sand blast, or as required |

| Export to | Singapore, Indonesia, Ukraine, Korea, Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada,USA, Egypt, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq, Russia, Malaysia, etc |

| Application | 1. Pancake Coil for ACR, General Engineering Applications2. LWC Coil for ACR, General Engineering Applications3. Straight Copper Tubes for ACR and Refrigeration4. Inner-grooved copper tube for ACR and Refrigeration5. Copper Pipe for Transportation System of water, gas, and oil6. PE-coated copper tube for water/gas/oil transportation system7. Semi-finished Copper tube for industrial applications |

Product Features:It has good electrical conductivity, thermal conductivity, corrosion resistance, and processing properties, and can be welded and brazed. It contains fewer impurities that reduce electrical conductivity and thermal conductivity, and a small amount of oxygen has little effect on electrical conductivity, thermal conductivity, and processing properties, but it is easy to cause "hydrogen disease", and it is not suitable for processing (annealing, annealing, welding, etc.) and use.

Table 1. chemical composition of Copper Plate/Sheet

| Chemical Requirements | ||||||||||

| CU+AG (%) | SN (%) | ZN (%) | PB (%) | NI (%) | FE (%) | SB (%) | S (%) | AS (%) | BI (%) | O (%) |

| ≥99.90 | ≤0.002 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.002 | ≤0.005 | ≤0.002 | ≤0.001 | ≤0.06 |

| Alloy | Chemical Composition | ||||

| QB | JIS /ASTM | Cu | P | O | Other |

| T2 | JIS C1100 | 99.9 | 0.015-0.040 | - | balance |

| TU | ASTM C10300 | 99.95 | 0.001-0.005 | - | balance |

| TP1 | JIS C1220 | 99.9 | 0.004-0.012 | - | balance |

Table 2. Typical mechanical properties for Copper Plate/Sheet

| Grade(China) | Grade(Japan) | Temper | Vickers Hardness (HV) | Tensile strength(Mpa) | Elongation(%) |

| T2/T3/TP1/TP2 | C11000/C1201 | M | - | ≥290 | ≥40 |

| C1220.etc. | Y4 | 75-125 | 325~410 | ≥35 | |

| Y2 | 85-145 | 340~460 | ≥25 | ||

| Y | 105-175 | 390~530 | ≥13 | ||

| T | - | ≥490 | - |

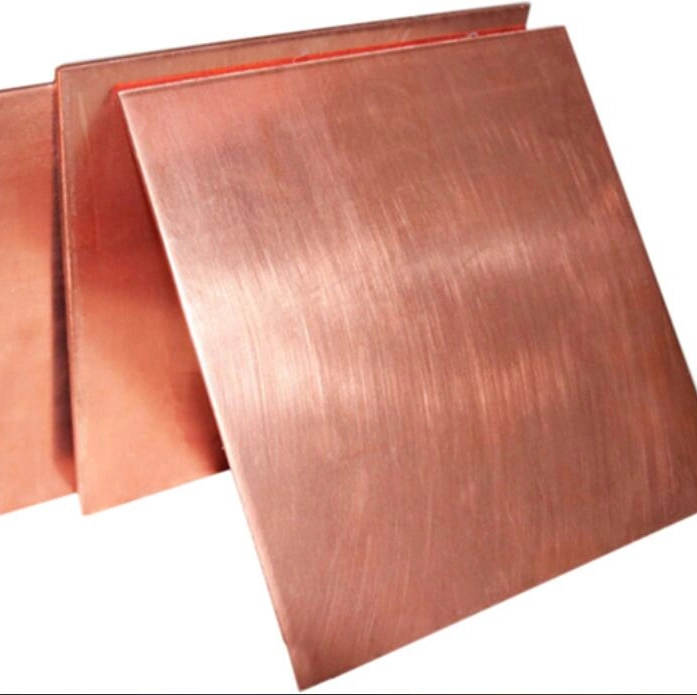

Detailed Photos

Company Profile

Exhibition

Feedback

FAQ

Q1. How long can make delivery?

If it is in stock, it is usually 5-10 days. Or, if there is no inventory, 15 working days, depending on the quantity.

Q2. Can you accept customize?

Yes. It can be customized as per the customers' request.

Q3. Are you trading company or manufacturer ?

We are professional manufacturer for steel products, and our company also is a very professional a trade company for steel

products.we can also provide a wide range of steel products.

Q4.What are the advantages of your company ?

We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q5: Do you provide after-sale service?

We provide after-sales service and offer 100% guarantee on our products.

Next: Chute and Hopper Liners Wear Plate/Dragline Bucket Q345 Steel Base Plate High Ccr Clad Liner Plate

Our Contact